I would be grateful if you considered purchasing one of my recipes

Key Lime Pie Recipe

Bayfield Waffles

How to make a V-65 Honda clutch nut tool

Before you start with my method, be sure to check the Other Methods and Option below, especially this one.

Parts needed:1 each, 1-3/16" 12 point socket.

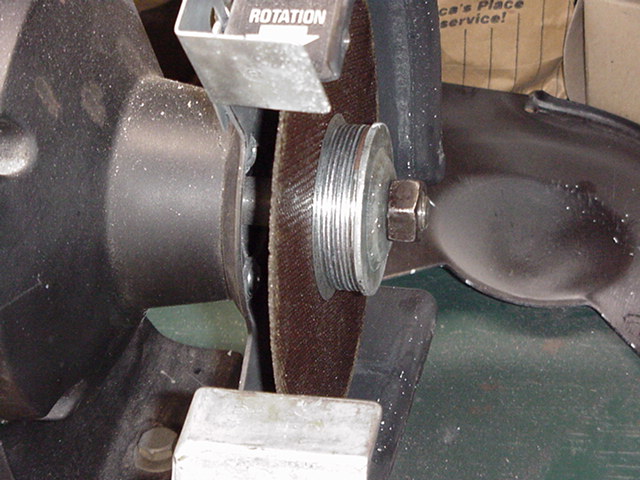

Tools I used:5" bench grinder with 1/2" arbor

Washers to stack on the arbor, on each side of the wheel

Thin cutoff wheel (1/16" or 1/8") with arbor adapter (if necessary)

Dremel toolThe arbor adapter is a little washer like thing that adapts the cutoff wheel to your grinder's arbor. If the hole in the cutoff wheel is larger than the arbor, you'll need this.

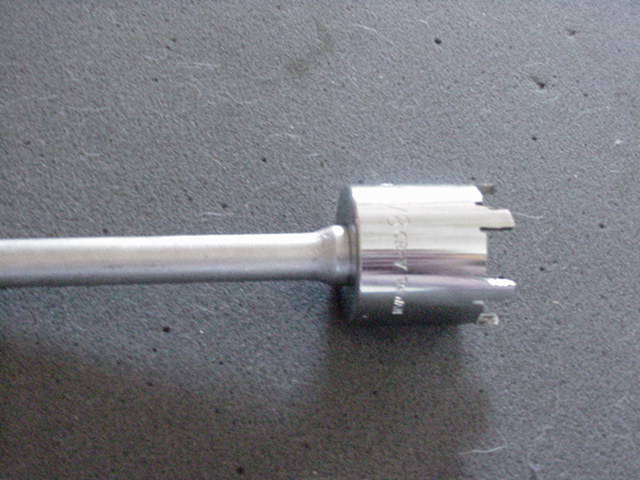

I used a socket extension to hold the socket while I cut the notches with above wheel. Make sure you wear body protection when you do this. If that cutoff wheel breaks, your body will thank you.

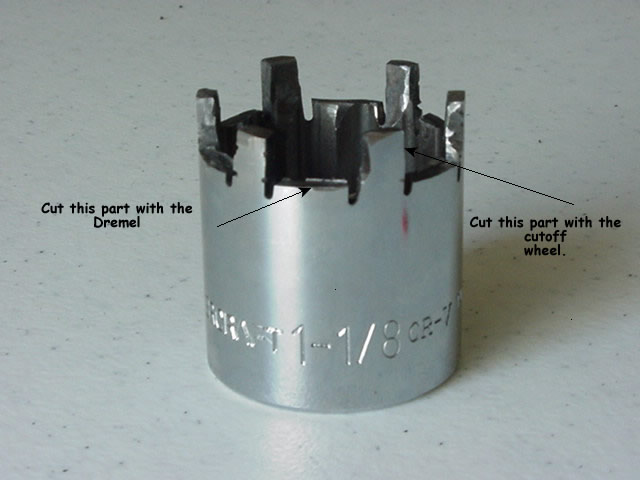

I used a 1-1/8" socket, but found it was a bit too small. I had to dremel away some of the inside so it would fit over the nut. One poster on http://www.v4hondabbs.com used a 1-3/16" and that might have worked better. I used a Dremel on the areas indicated below to cut a ways through the socket and then hit it with a ballpeen hammer to break it off. I left the socket on the extension and put the extension in a bench vise. This made the whole process easier.

I'm not a machinist, as you can see. It does work however.

Use this adobe file template to mark the socket. When you print this, make sure you set "Page Scaling" to none (Acrobat 6), or uncheck the "Fit to Page"(Acrobat 4) printing options. This will print to the proper scale. Keep in mind that this image is an outline of the actual nut. You can make the socket's "fingers" slightly wider than the image implies.

The fingers on the socket need to be fairly square and straight so they'll lock into the nut properly. My first attempt resulted in slippage off of the nut and could have rounded off the nut's notches. Be careful and do it right the first time. A Dremel tool is quite helpful with the finishing touches. Use the money you're saving by not buying the Honda tool to get you a Dremel.

Hopefully that does it. Let me know if I got anything wrong in the instructions. Comments welcome.

Thanks.

The following are posts found on the V-4 bbs that might give you some more insight. None of this is my material.

Already made clutch nut tool out of 1 3/16" socket, took 15 minutes to mark,cut lines,score with cut-off blade and break out tabs, no grinding. It works too , already took out clutch of spare motor.

or

Need to remove the clutch basket on your SabMag and don't have the special Honda tool? Well then, make your own. Use a 12-pt 1 1/8" socket and refer to this pic:

or

Take a 7/8" socket and a dremel with a cuttoff wheel. It helps to have a spare nut so you have a template. When making the notches, cut them at a slight angle, this will make the dogs-- no wait, that's an undercut trans--, constantly suck to the nut and not roll off of it. You don't have to cut all the notches, you can only make 4 prongs if you like, but you better have a good socket. I cut all mine and took only a few minutes with a bench grinder and a 1/8" wheel(not standard home grinder). Dremel will take ya some time.

I made one similar to this but with only 4 tangs. It's pretty easy if you have a dremel tool and some cutoff wheels. Hold the socket against the nut and mark the tang locations then start cutting. You don't have to be too accurate.

9/4/2005

I just received this E-mail. Good thinking, less work. I haven't tried it however.

I saw your article about the clutch nut tool. I found that a 32mm 12pt socket with every other point ground off fits perfectly over the nut, alittle snug and worked wondefully. It was real quick to make, about 2 minutes, and I used a cheaper socket purchased at K-Mart.

thanksJohnI attached photos for you.